Core | High Pressure CO2 Pumps

Need a compact laboratory CO2 pump or a high flow rate industrial pump, why not learn more a by clicking below

What Pump do you need?

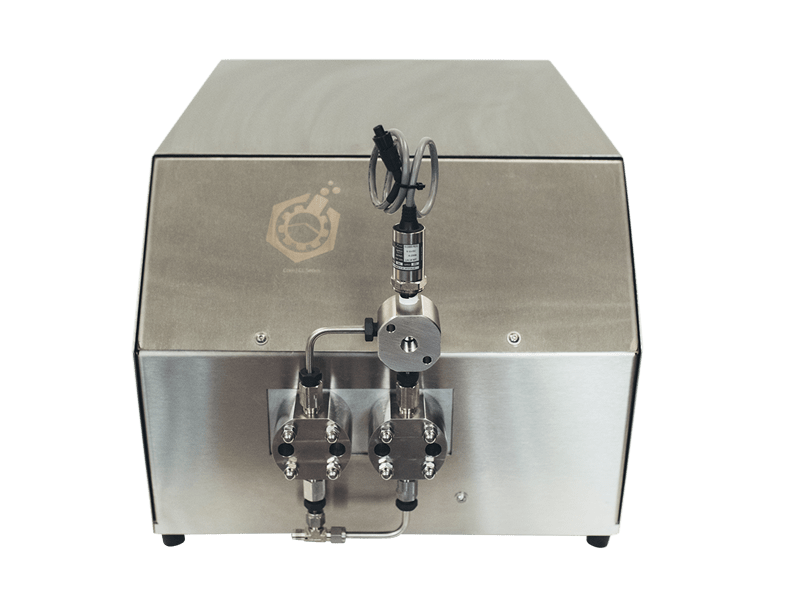

Core P50

Core P200

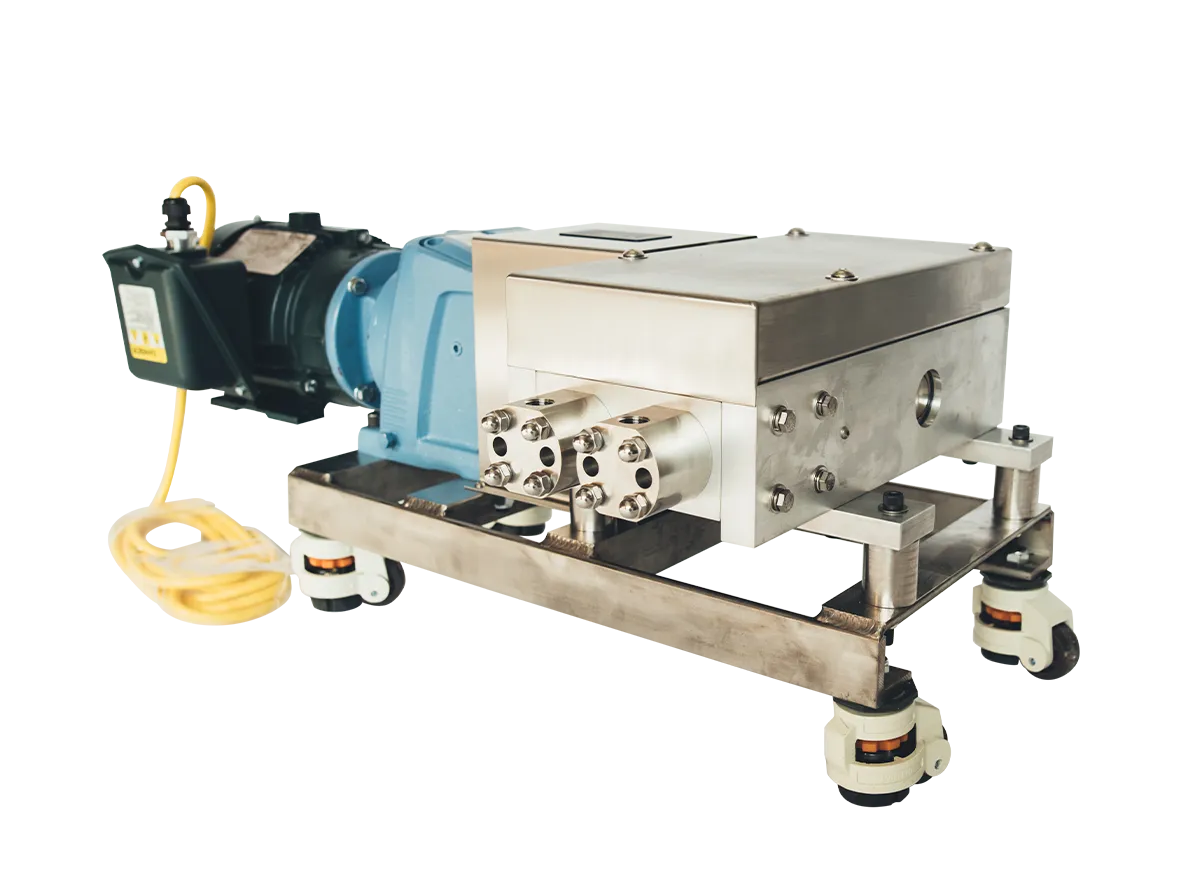

Core P300

Core P500

Core P1k

Core P251k

Core SFXIP10-410

SFXIPI-590

SFXIP45-920

SFXIP25-1640

Features

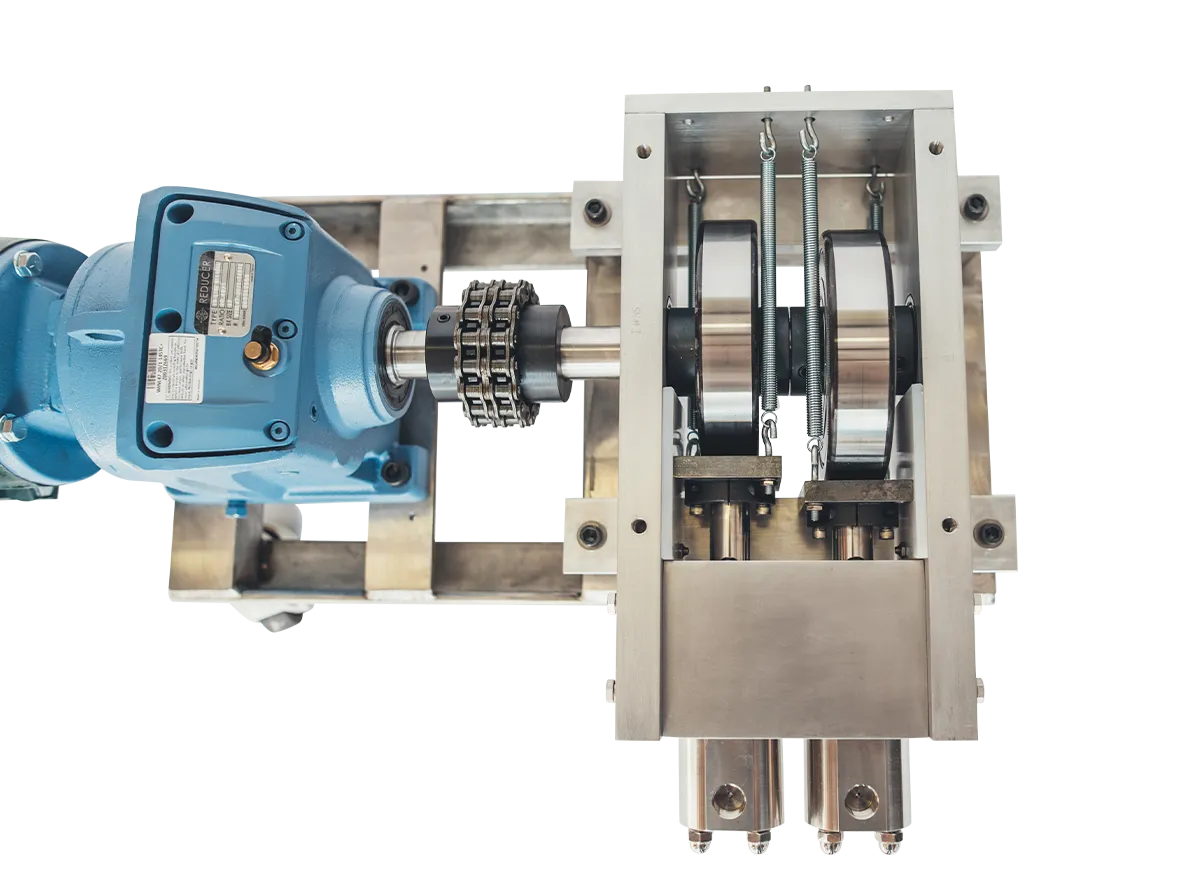

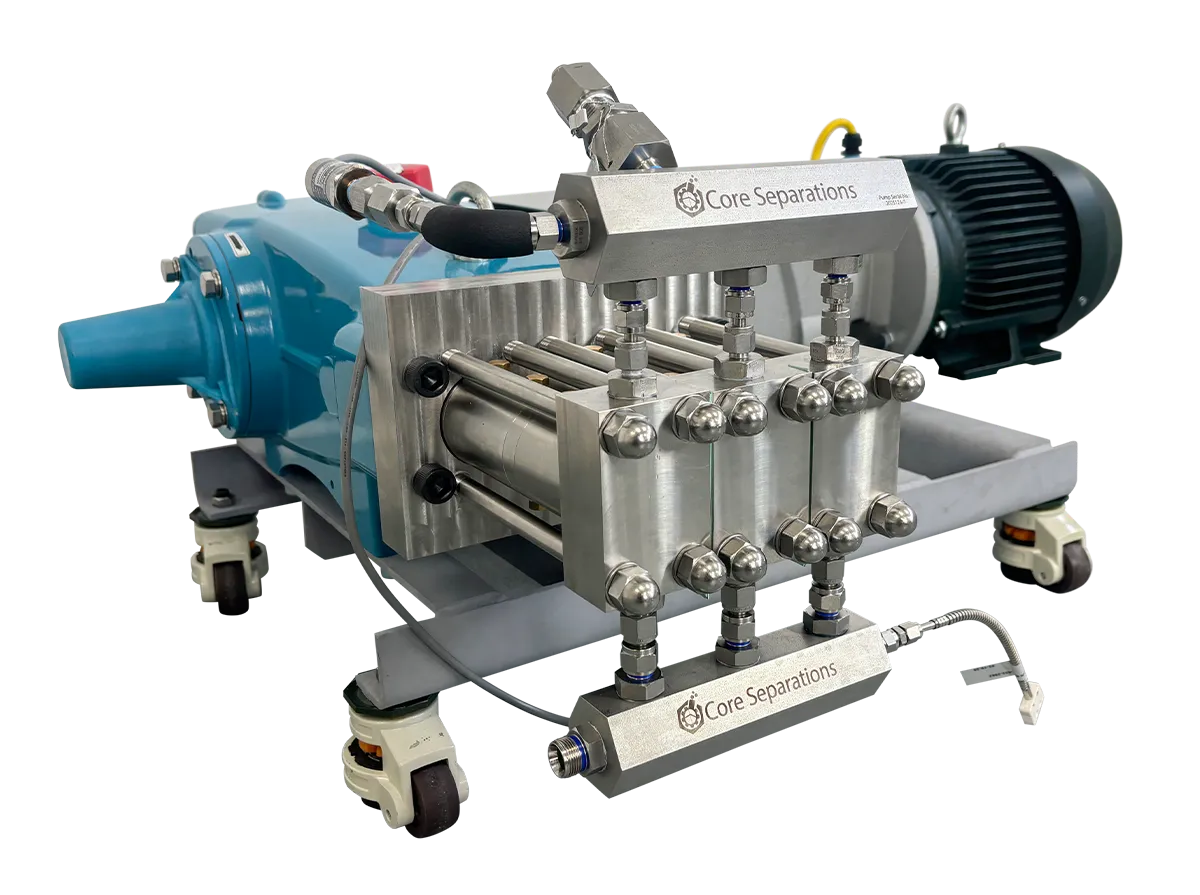

1. Ceramic Piston

The ceramic piston design reduces friction, resulting in less seal wear and lower maintenance. Dual stainless-steel heads with a cam driven piston assembly eliminates pulsed flow.

2. Efficient Cooling

With the heads machined with an innovative groove allowing the addition of cooling fluid, these pumps can easily be used to pump both solvents and CO2

3. Remote Diagnosis

Even with our robust designs, unforeseen problems can occur. In-order to ensure the pumps downtime is reduced to a minimal we can diagnosis issues remotely and offer a solution to ensure the pump is back running in the shortest time possible.

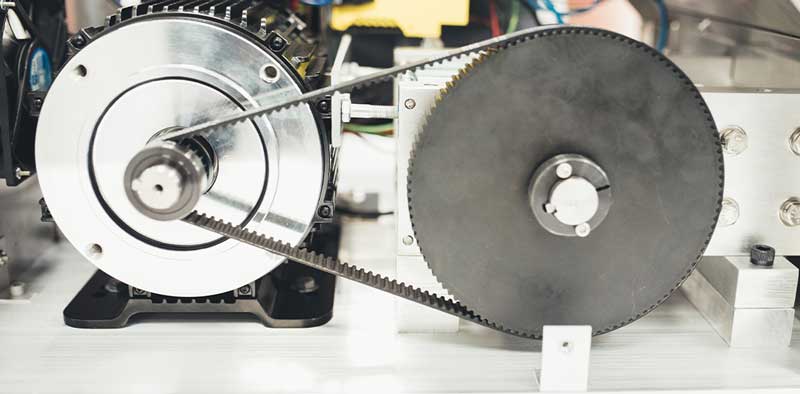

4. Precision Motor

Utilising either stepper or servo motors the CL pumps are capable of control, based on feedback from the pressure sensor or flow meter and can be regulated using a touch screen display, or via a PC through an ethernet connection.

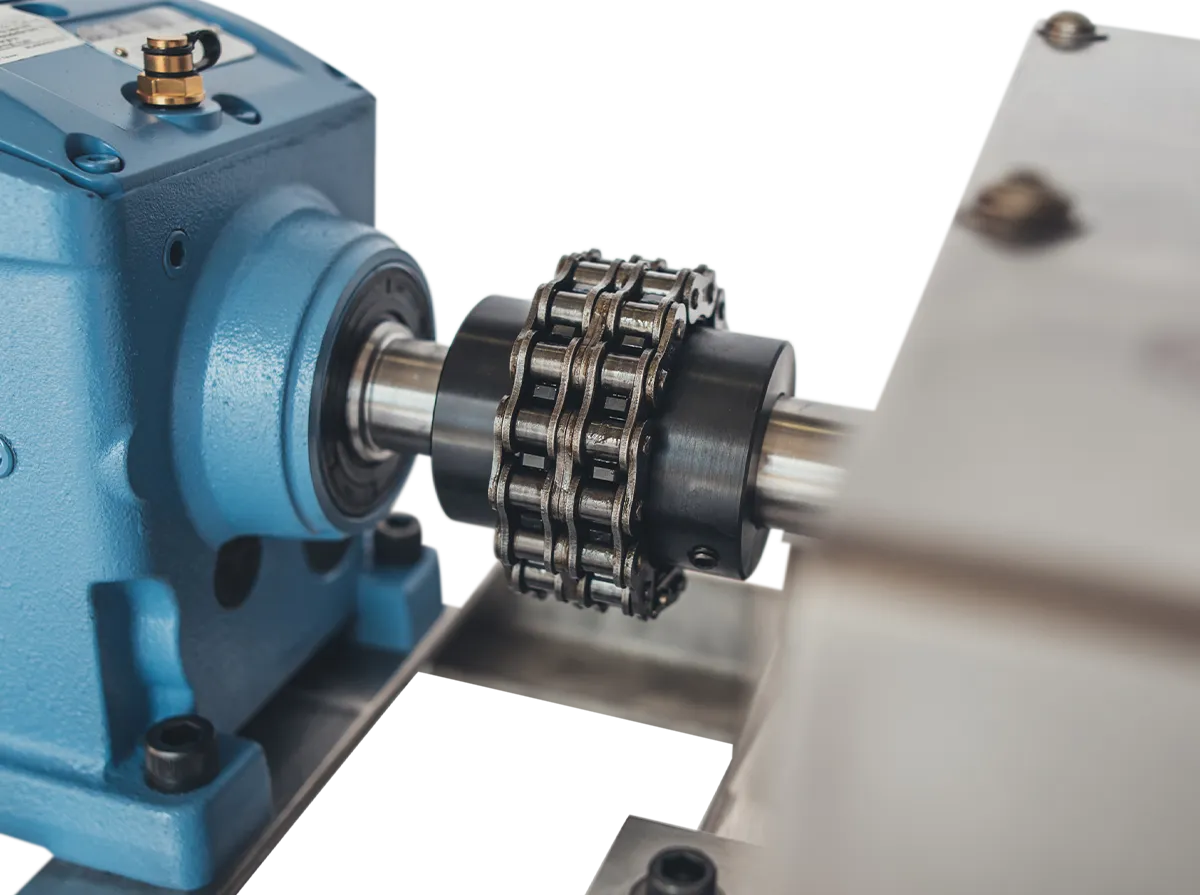

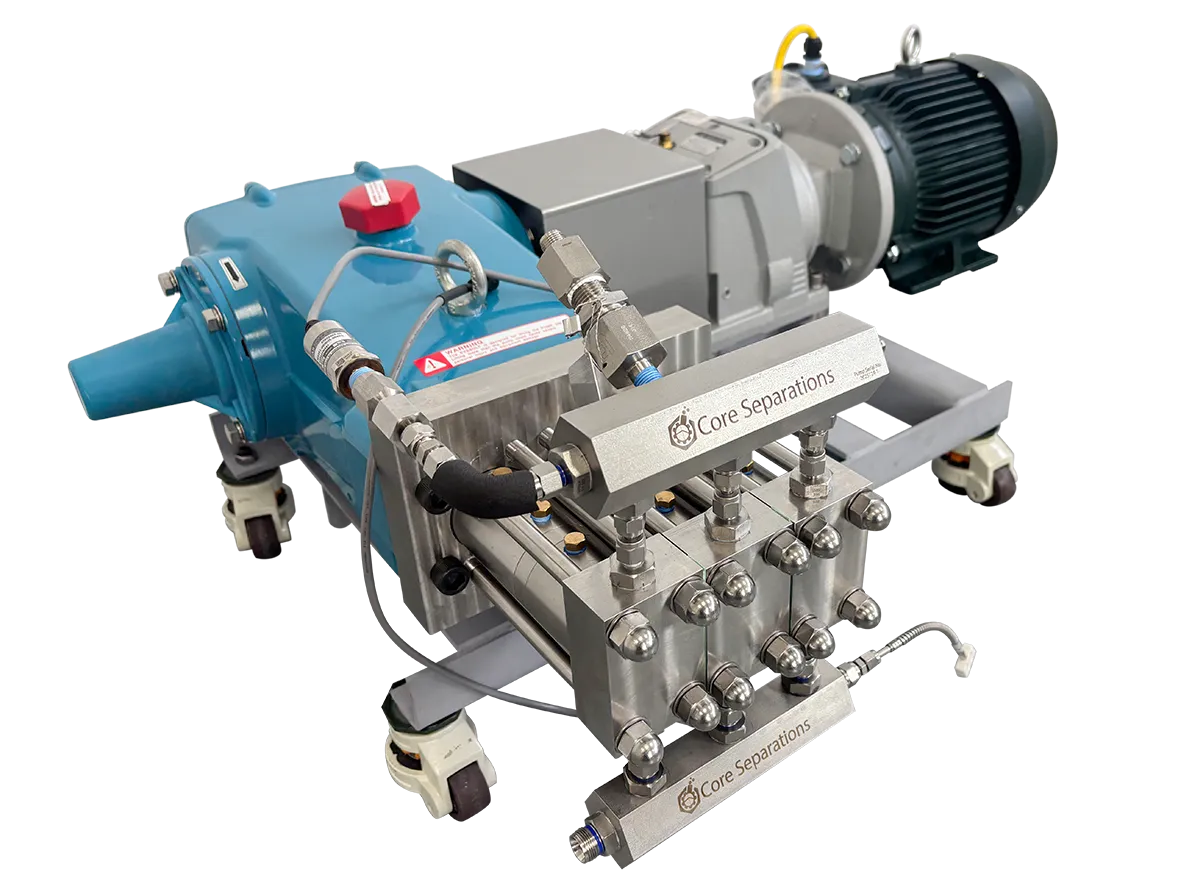

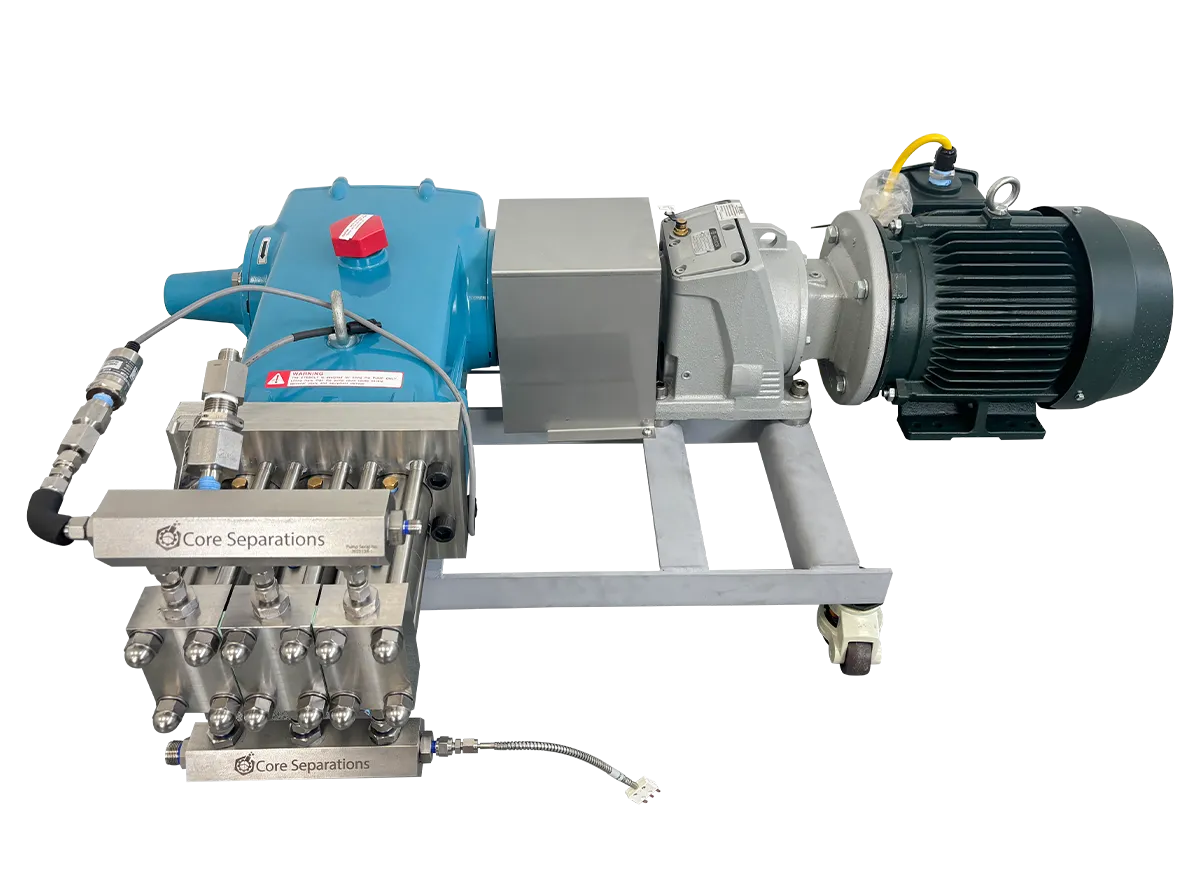

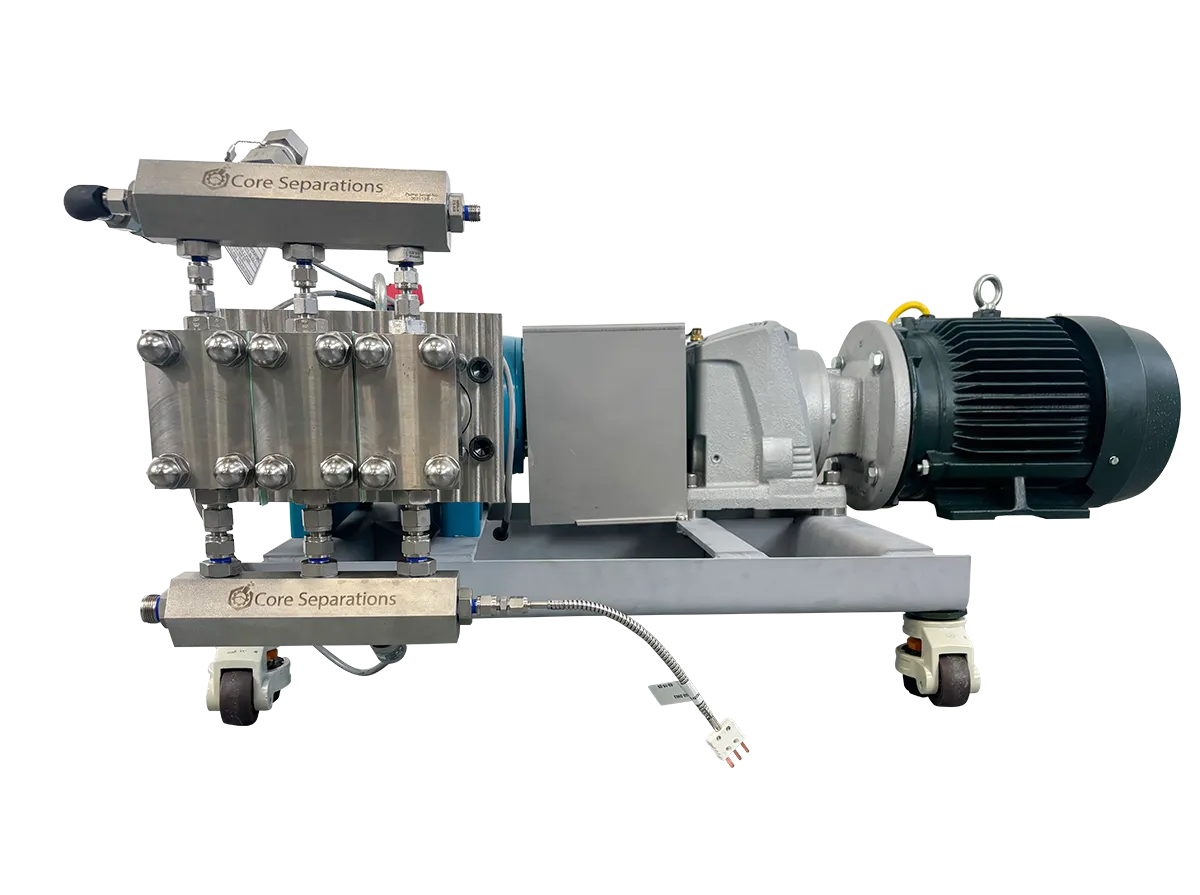

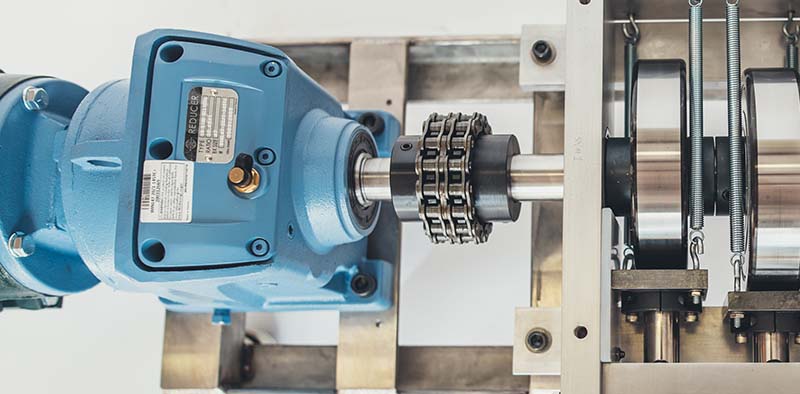

5. AC Motor GearBox Combo

Our Industrial series pumps use a tried and tested AC motor and gear box design that are highly energy efficient and have a proven long service life for all mechanical components. Combined with particularly low maintenance and operating costs, our pumps are well suited for the conditions required in manufacturing environments.

6. Dual Piston

Dual cam driven pistons designed to reduce pulsation during operation. Sealed for life bearings removing the requirement for an oil pan reducing the required maintenance over the lifetime of the pump.

7. Custom Check Valves

The pumping efficiency of any pump is the reliability of its check valves. That’s why are Core Separations we manufacture our own to the high possible standards, to make our pumps one of the most efficient on the market.

Have you seen our other Core | Products?

Core | Pumps

Core | Heat Exchangers

Core | Vessels